To maintain your booster pump, regularly inspect it for wear, leaks, and corrosion, and keep it clean from debris. Check electrical connections for tightness and signs of damage, and test the wiring and grounding system. Monitor pressure levels and lubrication schedules, replacing seals or worn parts promptly. Schedule professional servicing for complex issues. Proper upkeep prevents breakdowns and extends your pump’s life—continue optimizing your maintenance routine for lasting performance.

Key Takeaways

- Regularly inspect electrical connections, wiring, and grounding to ensure safety and proper functioning.

- Keep the pump clean, free of debris, and check inlet/outlet lines for blockages.

- Monitor seals for wear and replace them promptly to prevent leaks and maintain efficiency.

- Test and adjust pressure settings, and follow lubrication schedules for optimal performance.

- Conduct routine professional maintenance and keep detailed logs to prevent failures and extend lifespan.

Regularly Inspect the Pump and Its Components

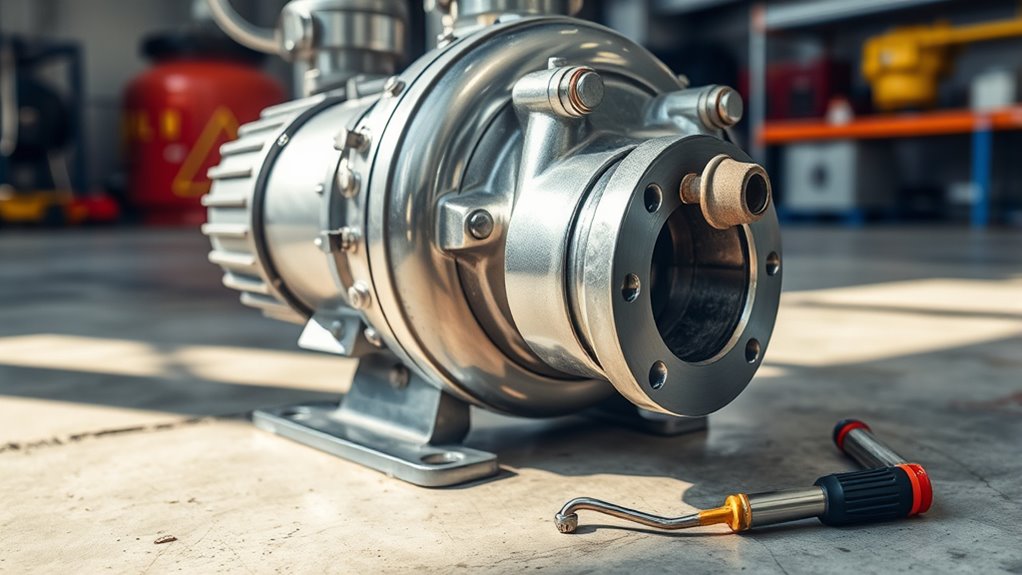

To keep your booster pump functioning at its best, it’s essential to regularly inspect it and its components. This helps maintain *ideal* pump efficiency and prevents costly breakdowns. Start by checking for signs of wear, leaks, or corrosion. Conduct vibration analysis to identify any unusual vibrations that could indicate misalignment or bearing issues, which can reduce efficiency and cause damage over time. Listen for abnormal noises, as they often signal underlying problems. Tighten loose fittings and inspect seals for leaks. Regular inspections allow you to catch issues early, ensuring your pump runs smoothly and efficiently. Implementing routine preventive maintenance can further extend the lifespan of your equipment. Keeping a maintenance log helps track inspection intervals and repairs, extending the lifespan of your booster pump and maintaining peak performance. Additionally, monitoring for environmental pollutants and emissions can help identify early signs of component degradation that might impact pump operation. Incorporating proper lubrication practices for moving parts can also significantly reduce wear and prolong pump longevity. Regularly checking the glycolic acid benefits for skin can offer insights into similar exfoliating processes that improve overall system health and longevity. Moreover, paying attention to component alignment ensures that parts operate harmoniously, reducing unnecessary strain on the pump.

Keep the Pump Clean and Free of Debris

You need to keep your booster pump clean to guarantee it runs efficiently. Regularly wipe down the surface to remove dirt and dust, and check for any blockages. Carefully clear out debris to prevent clogs that could damage the pump or reduce its performance. Monitoring for system vulnerabilities can help identify potential issues before they cause failures.

Regular Surface Cleaning

Have you ever considered how dirt and debris can impact your booster pump’s performance? Regular surface cleaning helps maintain peak pump efficiency and water quality. Dirt buildup on the pump’s exterior can cause overheating or corrosion, reducing its lifespan. Use a soft cloth or brush to wipe away dust, grime, and any accumulated debris. Avoid harsh chemicals that might damage seals or components. Make cleaning a routine, especially if your pump is exposed to dust or outdoor elements. Regular cleaning prevents dirt ingress and ensures smooth operation. By keeping the surface clean, you prevent dirt from entering the system and ensure smooth operation. Proper maintenance techniques can further extend the life of your pump and keep it functioning optimally. Regular cleaning also reduces the risk of hardware failures, saving you time and costly repairs in the long run. Additionally, understanding how external factors affect your equipment can help you take proactive measures. This simple step helps your pump operate efficiently and provides consistent water quality, saving you time and costly repairs in the long run.

Remove Blockages Carefully

When inspecting your booster pump, removing any blockages carefully is vital to keep it running smoothly. Blockage prevention ensures consistent performance and extends the pump’s lifespan. Always check for debris or obstructions that could hinder flow. To maintain pipe clearance and prevent future issues, follow these tips:

- Turn off the pump before inspection

- Gently dislodge debris with a soft brush or cloth

- Avoid forcing objects into pipes

- Regularly inspect inlet and outlet lines

- Clear any buildup near the pump area

Taking care during this process helps prevent damage and keeps your pump operating efficiently. Remember, cautious removal of blockages not only maintains performance but also reduces the risk of costly repairs down the line. Keep your booster pump clean and free of debris for peak operation. Additionally, understanding the suction power and cleaning modes of your pump can help you identify potential issues early and ensure optimal cleaning performance. Regular maintenance routines can also support efficient operation and prolong the life of your pump. Being familiar with the filter system can further aid in early detection of clogging and enhance overall functionality. Implementing vibration control measures can minimize mechanical wear and contribute to the longevity of your pump.

Check and Replace Worn or Damaged Seals

Seals play a crucial role in preventing leaks and maintaining the pump’s efficiency, so it’s essential to regularly inspect them for signs of wear or damage. During damage inspection, look for cracks, tears, or hardening that could cause leaks. If you notice any issues, prompt seal replacement is necessary to keep your booster pump running smoothly. Here’s a quick reference:

| Inspection Step | Action |

|---|---|

| Visual Damage Check | Look for cracks, tears |

| Leak Signs | Examine for fluid leaks |

| Seal Condition | Assess flexibility and wear |

| Replacement Need | Replace if damaged or worn |

Regularly checking and replacing worn or damaged seals ensures your pump remains efficient and leak-free, which is vital for optimal pump performance. Maintaining your seals also helps prevent fluid leaks, which can lead to decreased efficiency or pump failure over time. Additionally, understanding how to properly inspect seals can prolong the lifespan of your pump and reduce maintenance costs.

Monitor and Maintain Proper Electrical Connections

You need to regularly check your booster pump’s wiring to make sure it’s intact and secure. Make sure the pump is properly grounded to prevent electrical issues or safety hazards. Keeping these connections in good shape helps your pump run smoothly and safely. Regularly inspecting your performance cookies can also help identify any issues that might affect the pump’s operation. Additionally, ensuring your electrical system is protected by appropriate security measures can further prevent potential hazards. Proper grounding and adherence to electrical safety standards are essential components of maintaining a safe and efficient electrical connection for your pump. To ensure optimal performance, it’s important to periodically verify that all electrical components are functioning correctly and are free from corrosion or damage. Incorporating dynamic communication exercises for couples can promote better understanding and cooperation in maintaining your system.

Check Wiring Integrity

Regularly inspecting the wiring connections of your booster pump is essential for reliable operation. Focus on wiring inspection to ensure all connections are secure and free of corrosion or damage. Faulty wiring can disrupt electrical continuity, causing pump failure or inefficiency. To check wiring integrity, look for loose terminals, frayed wires, or signs of overheating. Use a multimeter to test for continuous electrical flow and confirm proper connections. Keep these tips in mind:

- Tighten loose terminals

- Replace frayed or damaged wires

- Clean corrosion from contacts

- Verify all connections are secure

- Test electrical continuity regularly

Performing these checks helps prevent electrical issues, ensuring your booster pump runs smoothly and efficiently. Proper wiring maintenance reduces downtime and prolongs the pump’s lifespan.

Ensure Proper Grounding

Proper grounding is essential for the safe and reliable operation of your booster pump. Ensuring grounding safety helps protect against electrical faults that could cause damage or pose shock hazards. Check that your pump’s grounding wire is securely connected to a proper grounding point, maintaining strong electrical continuity. A loose or corroded connection can compromise safety and reduce system efficiency. Use a multimeter to verify that the grounding system has minimal resistance, confirming good electrical contact. Regularly inspect the grounding components for signs of wear or damage, and replace any compromised parts immediately. Proper grounding not only enhances safety but also ensures your pump runs smoothly without interruptions caused by electrical issues. Prioritize grounding safety to keep your booster pump operating safely and effectively.

Test and Adjust Pressure Settings as Needed

To guarantee your booster pump operates efficiently, it’s essential to test and adjust the pressure settings regularly. Start by checking the pressure gauge calibration to ensure accurate readings. Use valve adjustment techniques to fine-tune pressure levels, preventing over-pressurization or insufficient flow.

Consider these key steps:

- Monitor pressure readings frequently

- Calibrate your pressure gauge for precision

- Adjust pressure settings smoothly with appropriate valve techniques

- Keep detailed records of any changes

- Test system performance after each adjustment

Lubricate Moving Parts According to Manufacturer Guidelines

After adjusting the pressure settings and testing system performance, it’s important to focus on maintaining the booster pump’s longevity and efficiency by lubricating its moving parts. Regular lubrication helps reduce wear and prevent overheating. Check the oil levels regularly, as recommended by the manufacturer, and top up or replace oil as needed. Follow the lubrication schedule provided in the user manual to ensure consistent maintenance. Use the correct type of lubricant specified for your pump to avoid damage. Be sure to clean any debris or old grease before applying fresh lubricant. Proper lubrication minimizes friction, extends component life, and keeps your booster pump operating smoothly. Staying on top of this routine is essential for peak performance and avoiding costly repairs.

Schedule Professional Servicing for Complex Maintenance

Because complex maintenance tasks can be challenging and require specialized knowledge, scheduling professional servicing guarantees your booster pump stays in peak condition. Experts can maximize pump efficiency and detect issues early through methods like vibration analysis. Regular professional checkups help identify misalignments, worn bearings, or impeller problems that can hinder performance.

Consider these benefits:

- Improved pump efficiency and longevity

- Accurate vibration analysis for early fault detection

- Precise calibration to maintain ideal flow

- Expert inspection of critical components

- Prevention of costly breakdowns

Scheduling professional servicing ensures your booster pump operates reliably, saving you time and money. Trust trained technicians to handle complex tasks that go beyond routine maintenance, keeping your system running smoothly and efficiently.

Keep Accurate Records of Maintenance Activities

Maintaining detailed records of all maintenance activities guarantees you can track your booster pump’s performance and identify recurring issues. Good record keeping practices help you monitor when maintenance was performed, what parts were replaced, and any problems encountered. This information makes maintenance scheduling more effective, ensuring you don’t overlook routine checks or repairs. By keeping accurate logs, you can spot patterns that indicate potential failures before they happen, saving time and money. Use a dedicated logbook or digital system to document servicing dates, technician notes, and parts used. Regularly review these records to stay ahead of maintenance needs. Clear, consistent documentation is essential for maintaining your booster pump’s efficiency and extending its lifespan.

Frequently Asked Questions

How Often Should I Replace the Pump’s Filters?

You should check your pump’s filters regularly to guarantee peak performance. Typically, filter replacement is needed every 3 to 6 months, depending on usage and water quality. Regular filter replacement helps extend your pump’s lifespan by preventing clogging and damage. Keep an eye on signs of reduced flow or strange noises, and replace filters promptly to maintain efficiency and protect your investment.

What Signs Indicate the Pump Needs Immediate Repair?

You’ll want to watch for signs like excessive pump vibration and unusual noises, which indicate your booster pump needs immediate repair. If it starts vibrating more than usual or makes strange sounds, don’t overlook it. These issues could signal mechanical problems or blockages. Addressing them quickly prevents further damage and keeps your system running smoothly. Regular inspections can help catch these warning signs early and ensure your pump functions efficiently.

Can I Troubleshoot Electrical Issues Myself Safely?

When troubleshooting electrical issues, you might wonder if you can do it safely yourself. Always prioritize electrical safety by turning off power before inspecting any wiring or components. Follow troubleshooting basics, like checking for loose connections, blown fuses, or tripped circuit breakers. If you’re unsure or uncomfortable, it’s best to consult a professional. Remember, safety comes first—never risk working on electrical parts without proper knowledge and precautions.

How Do Temperature Changes Affect Pump Performance?

Imagine your booster pump operates in a space with fluctuating temperatures. During hot days, temperature regulation becomes essential; heat causes thermal expansion of pump components, which can lead to leaks or reduced efficiency. Conversely, cold weather may cause parts to contract, affecting seals and performance. These temperature changes impact your pump’s operation, so monitoring and managing environmental conditions helps prevent damage and guarantees consistent performance.

What Is the Typical Lifespan of a Booster Pump?

A booster pump typically lasts between 8 to 15 years, depending on usage and maintenance. You can extend its lifespan by regularly checking pump efficiency and sticking to maintenance schedules. Proper upkeep, like cleaning components and replacing worn parts, helps prevent breakdowns. Keep an eye on performance signs, and timely maintenance guarantees your pump runs smoothly longer, saving you money and avoiding unexpected failures.

Conclusion

By tending to your booster pump like a vigilant gardener tending delicate blooms, you guarantee it remains healthy and reliable. Regular inspections and timely care act as the nourishing sunshine and water that keep it thriving. When you stay attentive, you prevent small issues from blossoming into costly breakdowns. Treat your pump with the same dedication and watch it perform seamlessly, like a well-rehearsed symphony—truly the heartbeat of your system’s smooth operation.