To sustain your pressure pool cleaner, regularly inspect and clean the filter basket to keep it debris-free and functioning efficiently. Check hoses and fittings for cracks or leaks, replacing damaged parts promptly. Keep water pressure and flow rate balanced for peak cleaning, and inspect moving parts for wear—lubricate as needed. Proper deployment and storage also help prevent issues. Continue exploring these tips to guarantee your cleaner performs at its best all season long.

Key Takeaways

- Regularly inspect and clean the filter basket, replacing it if damaged or clogged.

- Check hoses and fittings for leaks, cracks, or damage, tightening or replacing as needed.

- Maintain proper water pressure and flow rate, adjusting the pump pressure for optimal cleaning.

- Ensure the cleaner is properly positioned in high-traffic, well-flow areas during operation.

- Store the cleaner in a dry, sheltered location after cleaning and dry all parts thoroughly.

Inspecting and Cleaning the Filter Basket

Regularly inspecting and cleaning the filter basket is essential to keep your pressure pool cleaner operating efficiently. It ensures proper filter maintenance and prevents clogs that can hinder debris removal. Start by turning off the cleaner and removing the basket from the unit. Check for leaves, dirt, and other debris that may have accumulated. Rinse the basket with a garden hose to remove dirt and debris thoroughly. If the filter mesh is damaged or clogged, replace the basket to maintain peak performance. Regular cleaning prevents debris buildup that can reduce suction and cleaning effectiveness. Keeping the filter basket clean also prolongs the lifespan of your pressure pool cleaner. Proper filter maintenance can also enhance your vehicle’s performance and reliability. Additionally, understanding the optimal angles for pinball machines can help you adjust your equipment for better operation. Incorporating AI-driven solutions in maintenance routines can further optimize your pool cleaning process. Make this a routine part of your pool maintenance to keep your cleaner working smoothly and your pool sparkling clean.

Checking and Replacing the Hose and Connections

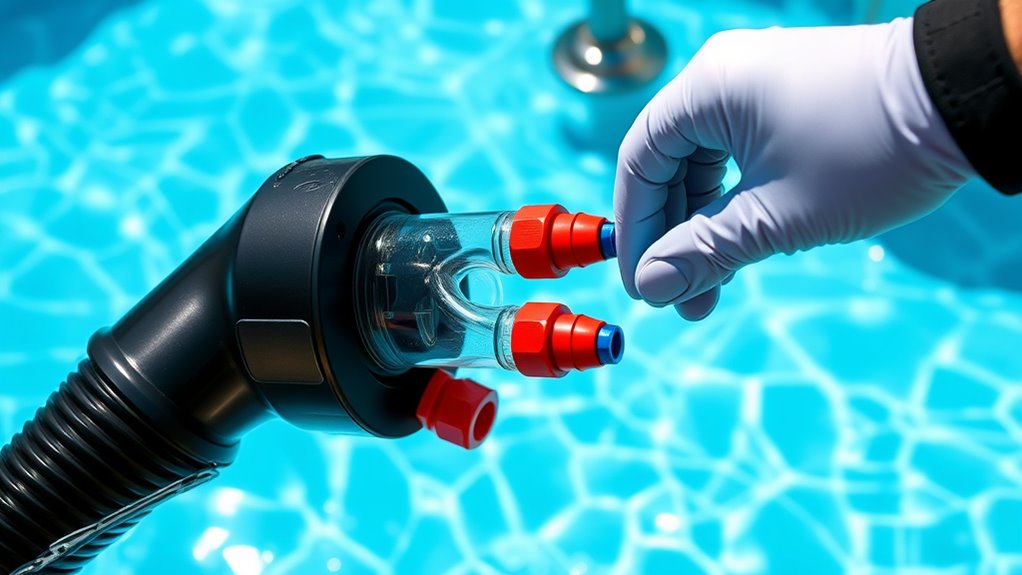

Regularly inspect your pool cleaner’s hose for cracks or leaks, and tighten any loose fittings to keep it working efficiently. If you notice worn or damaged components, replacing them promptly will prevent more serious issues. Staying on top of these checks guarantees your pressure cleaner stays in top shape.

Inspect Hose Regularly

Since hoses are exposed to constant water flow and debris, it’s vital to perform regular hose inspection to spot wear or damage early. Check for cracks, leaks, or holes along the entire length of the hose. Pay special attention to connection points, ensuring they fit snugly without leaks. Loose or damaged connections can reduce cleaning efficiency and cause water leaks. During inspection, also look for any kinks or twists that might restrict water flow. If you notice any signs of deterioration, replace the hose promptly to prevent further issues. Regular connection checks help guarantee the hose remains secure and functional. Using durable hose materials, such as stainless steel hoses, can also enhance longevity. Incorporating high-quality connectors can further prevent leaks and improve overall performance. Additionally, inspecting the filter and pump components regularly ensures optimal operation and prevents damage to the system. Being aware of corrosion resistance features in hose materials can extend the lifespan of your equipment. By staying proactive with these simple inspections, you’ll keep your pressure pool cleaner operating smoothly and extend its lifespan.

Tighten Loose Fittings

Loose fittings can cause leaks and reduce your pool cleaner’s efficiency. Check the hose connectors and fittings regularly to confirm they’re tight. If you notice any leaks, tighten the connections firmly but avoid over-tightening, which can damage the fittings. While inspecting, also examine the hose for cracks or wear that might lead to leaks. Proper hose connection is vital for excellent filter maintenance, as a secure fit helps maintain pressure and suction. Additionally, ensuring your equipment uses automation technologies can prevent operational issues and improve maintenance routines. If you find damaged or worn fittings, replace them to prevent further issues. Keep the fittings clean and free of debris to guarantee a snug connection. Regularly tightening loose fittings keeps your pressure pool cleaner running smoothly and extends its lifespan. Maintaining proper connection techniques can further help prevent leaks and improve overall performance. Ensuring a secure fit of all connections is essential for optimal operation and to avoid costly repairs. Incorporating regular inspections into your maintenance schedule can identify potential problems early and save time and money. Using correct tightening methods can also prevent stripping threads or damaging the fittings, ensuring a longer-lasting seal.

Replace Worn Components

Over time, hoses and connections can wear out, crack, or become damaged, reducing your pressure pool cleaner’s effectiveness. Regular component replacement guarantees ideal performance and prevents costly repairs. Inspect hoses and connections frequently for signs of wear or leaks. If you notice cracks, brittleness, or loose fittings, it’s time to replace those worn components. Upgrading system parts can also enhance your cleaner’s efficiency, especially if newer, more durable options are available. Replacing worn hoses and connections is straightforward and essential for maintaining proper water flow and suction. Additionally, understanding the importance of projector contrast ratio can help you appreciate how component quality impacts overall system performance. Recognizing pressure system integrity is crucial to ensure your pool cleaner functions optimally. Staying attuned to spiritual guidance can also help you recognize when it’s time for maintenance or upgrades in your equipment. By staying on top of these replacements, you guarantee your pressure pool cleaner operates smoothly, saving you time and effort in the long run. Keep your system upgraded and parts in good condition for best results.

Clearing Blockages in the Intake and Nozzles

Blockages in the intake and nozzles can considerably reduce your pool cleaner’s efficiency, so it’s important to address them promptly. An intake blockage occurs when debris or dirt clogs the intake port, limiting water flow. To clear it, turn off the cleaner, detach the hose, and inspect the intake for obstructions. Remove debris carefully to avoid damaging the filter. Regularly checking and cleaning these parts guarantees maximum water flow and proper cleaning performance. Using a cleaning brush or small tool can help dislodge stubborn debris from the nozzles. Nozzle obstruction happens when dirt or debris blocks the nozzles, impairing spray and movement. Use a brush or small tool to gently clear any obstructions from the nozzles. Regular maintenance like this prevents buildup and ensures consistent operation. Staying proactive about clearing intake blockages and nozzle obstructions keeps your pressure pool cleaner running smoothly and extends its lifespan. Additionally, understanding the electric power generation aspects of pool cleaners can help optimize their performance and efficiency. Proper maintenance of electrical components ensures safety and longevity of your equipment.

Maintaining Proper Water Pressure and Flow Rate

Maintaining the correct water pressure and flow rate is essential for your pressure pool cleaner to operate effectively. Proper flow ensures debris removal, while consistent pressure prevents damage. To optimize performance, regularly check your pump’s pressure gauge and adjust as needed. Keep your pool’s chemical balance in check, as imbalanced water can hinder flow and promote algae growth. Use this table to understand flow and pressure relationships:

| Water Pressure | Flow Rate | Impact |

|---|---|---|

| Too high | Excessive | Damage parts |

| Too low | Insufficient | Poor cleaning |

| Proper | Balanced | Effective cleaning |

| Imbalanced | Unstable | Algae prevention issues |

Monitoring these factors helps maintain a clean, algae-free pool and prolongs your cleaner’s lifespan. Additionally, understanding the Security Zone can help you safeguard your pool equipment from theft or vandalism. Ensuring your pool system operates within the recommended noise levels of modern heat pumps can also contribute to a more comfortable environment around your pool area. Regularly inspecting your pool water chemistry helps prevent issues related to flow and pressure imbalance.

Inspecting and Replacing Worn or Damaged Parts

Regularly inspecting your pressure pool cleaner for worn or damaged parts is essential to guarantee it functions effectively. Check the filter regularly and perform filter replacement if you notice debris or reduced water flow. A clean filter ensures ideal suction and cleaning performance. Additionally, inspect the hoses for cracks, leaks, or blockages, and replace any damaged sections promptly. Damaged hoses can reduce pressure and hinder the cleaner’s movement. Look for loose fittings or worn-out seals, and tighten or replace them as needed. By staying vigilant with these inspections, you prevent minor issues from escalating into costly repairs. Regularly replacing worn parts and maintaining clean filters keep your pressure pool cleaner operating smoothly and extend its lifespan.

Lubricating Moving Components

To keep your pressure pool cleaner running smoothly, you need to lubricate its moving parts regularly. Choose the right lubricant to avoid damage and guarantee proper function. Apply the lubricant carefully and consistently to keep everything operating efficiently.

Subheading 1: Choose Appropriate Lubricant

Choosing the right lubricant is essential for keeping your pressure pool cleaner’s moving parts functioning smoothly. Proper lubricant selection guarantees minimal wear and prevents sticking or squeaking. When considering lubricant, focus on compatibility with plastic and rubber components, corrosion resistance, and water-proof properties.

Remember, application frequency depends on usage, but avoid over-lubricating, which can attract dirt. Use a small amount and apply it evenly to moving parts.

- Select water-resistant, non-gumming lubricants

- Avoid petroleum-based oils on plastic parts

- Use lubricants designed for pool equipment

- Apply after cleaning or as recommended by the manufacturer

- Check lubricant condition periodically to avoid dryness

Subheading 2: Apply Carefully and Regularly

Applying lubricant carefully and consistently helps keep your pressure pool cleaner’s moving parts operating smoothly. Regular lubrication reduces wear and prevents parts from sticking or squeaking. To stay effective, incorporate lubrication into your cleaning schedule, ensuring you don’t forget routine maintenance. Before applying, check that your equipment is properly calibrated for peak performance. Use the recommended lubricant type for your cleaner’s components and apply it sparingly, focusing on joints, gears, and hinges. Avoid over-lubricating, which can attract dirt and debris. Consistent lubrication minimizes unnecessary strain on the motor and other moving parts, extending your cleaner’s lifespan. Remember, well-maintained components operate more efficiently, saving you time and effort during cleaning sessions. Proper application of lubricant is essential for peak performance and durability.

Ensuring Correct Deployment and Positioning

Ensuring your pressure pool cleaner is correctly deployed and positioned is essential for effective cleaning. Proper placement helps it cover the entire pool surface while maintaining energy efficiency. Before starting, check that the pool’s chemical balance is ideal to prevent debris buildup and ensure smooth operation. Position the cleaner in areas with good water flow to maximize coverage. Make sure the hoses are free of kinks and securely connected. Verify the cleaner’s weight is balanced to avoid it sticking to one spot. Regularly inspect and adjust the cleaner’s position during operation to prevent missed spots. These steps improve cleaning efficiency, help conserve energy, and keep your pool water crystal clear.

- Keep hoses free of tangles for smooth movement

- Position the cleaner in high-traffic areas

- Adjust the float and brushes for better coverage

- Check water flow for ideal operation

- Maintain proper pool chemical balance

Storing Your Cleaner During Off-Season

When storing your pressure pool cleaner during the off-season, proper techniques are vital to keep it in top shape. You should safeguard it from the elements to prevent damage and deterioration. Taking these steps ensures your cleaner stays ready for use when swimming season resumes.

Proper Storage Techniques

To keep your pressure pool cleaner in good condition during the off-season, proper storage is essential. You want to prevent damage and ensure it’s ready for use when the season resumes. Before storing, clean the cleaner thoroughly and ensure the pool’s chemical balance is stable to prevent algae buildup. Store it in a cool, dry place away from direct sunlight to avoid deterioration. Make sure to disconnect hoses and store them properly to prevent cracking. Keep the cleaner elevated off the ground to prevent moisture damage. Regularly check stored equipment for any signs of corrosion or mold. Proper storage helps maintain your cleaner’s performance and extends its lifespan.

- Clean and dry all parts thoroughly

- Store in a cool, dry location

- Keep hoses loosely coiled

- Elevate the cleaner off the ground

- Check periodically for damage

Protecting From Elements

Proper storage doesn’t end with just cleaning and organizing your pressure pool cleaner; it also involves safeguarding it from environmental elements that can cause damage during the off-season. Exposure to rain, snow, and sunlight can deteriorate components, so store your cleaner in a dry, sheltered area. Before storing, ensure the water chemistry is balanced to prevent corrosion or mold growth. Disconnect the power supply and check electrical safety, making sure no cords or connections are exposed to moisture. Store the cleaner in a cool, clean spot away from direct sunlight and extreme temperatures. Cover it with a tarp or protective cover to shield it from dust and debris. Proper protection ensures your pressure pool cleaner remains in good condition for when you need it again.

Conducting Regular Performance Tests

Regular performance tests are essential to guarantee your pressure pool cleaner operates efficiently. By checking its performance regularly, you can catch issues early and prevent costly repairs. Focus on key areas such as filter maintenance, ensuring the filter is clean and unobstructed for ideal suction. Inspect the hose for cracks or leaks and perform hose repair if needed to maintain proper water flow. Observe the cleaner’s movement across the pool surface; uneven coverage may signal motor or wheel problems. Monitor water pressure and flow rate to confirm the cleaner is functioning at best performance. Regular testing helps you identify minor issues before they become major problems, keeping your pool clean and your equipment in top shape.

Regular testing ensures your pressure pool cleaner runs efficiently and prevents costly repairs.

- Check for consistent cleaning coverage

- Inspect and clean the filter thoroughly

- Examine the hose for leaks or damage

- Test water pressure and flow rate

- Observe the cleaner’s movement pattern

Troubleshooting Common Issues

When your pressure pool cleaner isn’t working as it should, identifying the root cause quickly can save you time and frustration. First, check the pool’s chemical balance; imbalanced chemicals can affect the cleaner’s performance. If the water isn’t properly balanced, consider alternative cleaning methods, like manual brushing or skimming, until the issue is resolved. Examine the hoses and connections for leaks or blockages, and ensure the pressure valve is functioning correctly. Dirty or clogged filters can also reduce efficiency, so clean or replace them as needed. If these steps don’t fix the problem, evaluate whether the cleaner’s parts are worn or damaged. Troubleshooting common issues promptly helps maintain peak performance and keeps your pool clean.

Frequently Asked Questions

How Often Should I Replace the Pressure Pool Cleaner’S Hoses?

You should replace your pressure pool cleaner’s hoses when they show signs of wear or leaks. Regular hose replacement helps prevent breakdowns and keeps your cleaner functioning efficiently. To extend the lifespan, inspect the hoses monthly for cracks or brittleness, and clean or repair them as needed. Proper maintenance and timely hose replacement boost performance and lifespan, ensuring your pool stays clean without frequent repairs.

Can I Use Household Cleaners to Clean the Cleaner’s Parts?

You shouldn’t use household chemicals to clean your pressure pool cleaner’s parts because they can damage the equipment. Instead, clean the parts regularly with a mild soap and water to maintain peak performance. Follow a consistent cleaning frequency, ideally after every few uses, to prevent buildup and ensure longevity. Avoid harsh cleaners, and always rinse thoroughly to keep your cleaner in top shape for the swimming season.

What Are Signs of a Worn or Damaged Pressure Pool Cleaner?

If your pressure pool cleaner shows signs of leaks or reduced suction, it’s likely worn or damaged. You might notice water escaping from seals or hoses, or the cleaner struggling to pick up debris. These issues indicate parts like hoses, seals, or the turbine may need inspection or replacement. Addressing leaks quickly and checking for obstructions helps restore peak performance and prevents further damage to your pool cleaner.

How Do I Adjust the Cleaner for Different Pool Sizes?

To handle pool size adjustments, start by consulting your cleaner’s manual for specific calibration steps. You’ll want to adjust the hose length or pressure settings to match your pool’s size, ensuring ideal coverage. Proper cleaner calibration involves checking the flow rate and pressure, then tweaking accordingly. This way, your pressure pool cleaner works efficiently across different pool sizes, giving you a spotless pool with minimal effort.

Is It Necessary to Calibrate the Pressure Settings Regularly?

You should regularly calibrate your pressure sensor to guarantee ideal cleaner performance. Proper calibration helps maintain consistent pressure readings, which directly impacts cleaning frequency and efficiency. Neglecting this step can cause your cleaner to underperform or overwork, leading to potential damage. Make it a habit to check and calibrate the pressure sensor periodically, especially if you notice irregular cleaning patterns or pressure fluctuations, to keep your pool cleaner running smoothly.

Conclusion

By regularly inspecting and maintaining your pressure pool cleaner, you keep it running smoothly—like a well-oiled machine. Think of it as giving your cleaner a spa day, ensuring every part works harmoniously. With a little effort, you’ll enjoy crystal-clear water and hassle-free cleaning all season long. Remember, a well-maintained cleaner isn’t just a tool; it’s your pool’s best friend, turning maintenance into a breeze and your swimming days into pure bliss.